Compared to mechanical manual regulators, a proportional air pressure regulator has numerous benefits. With consistent upstream flow rates, a manual regulator can most efficiently maintain pressure downstream. The digital pressure regulator is specifically made to run mechanics. Even when the incoming pressure to the regulator varies, electronic pressure regulators keep the output pressure constant in a pressured system.

What is a proportional air pressure regulator?

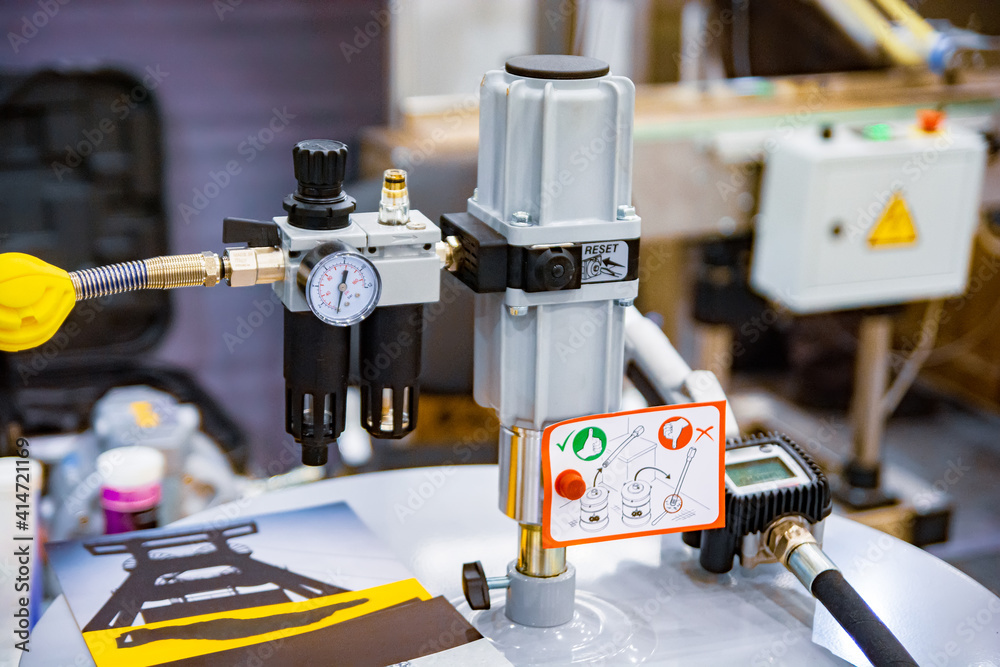

Proportional air pressure regulators are used to lower pressure levels, which reduces expenses and adds a measure of safety. Furthermore, it is frequently necessary to carefully monitor the ideal air pressure control of pneumatic equipment in order to achieve dependable performance. Air pressure regulators come in a variety of styles at MGA, from general-purpose units that can handle typical industrial applications to highly specialized precision regulators.

Purpose of an air pressure regulator

Proportional Air pressure regulators are used to provide a constant outlet of pressure, separately from the inlet pressure or flow. They are most commonly used to reduce the pressure level required for downstream equipment, stabilize the force applied to cylinders or minimize pressure variation. Compared to the traditional electric air pressure regulator, the digital air pressure regulator has a better design. Using an electronic pressure control valve will allow you to achieve the correct air pressure level. Let’s say you want the procedure to be carried out with constant air pressure.

It’s easy to keep the right air pressure level. As a result, both the product quality and general process effectiveness are improved. It has an air pressure, change-detecting mechanical controller. The valve is under full-flow pressure while it is circumventing its full-rated flow. The pressure differential or pressure override are other names for the difference in full-flow and cracking pressure. In some circumstances, air pressure override is acceptable. If gas escapes through the valve before reaching the maximum setting, it might waste power and be detrimental. As a result, the maximum system pressure may be higher than the specifications of the other elements.

Electronic Pressure Control Valves

In almost every pneumatic and hydraulic system, proportional air pressure regulators are present. They assist in a number of tasks, such as lowering system pressures below a certain threshold and maintaining a specific pressure level in a particular circuit segment. Relief, reduction, sequence, counterbalance, safety, and unloading valves are a few of the several pressure control valves kinds.

All of them, with the exception of decreasing valves, are typically closed valves. An electronic air pressure valve’s main objective is to lower exit pressure by reducing incoming pressure, also referred to as pressure rises. To create the requisite pressure control for the majority of these valves, a restriction is required. One exception to this rule is the externally piloted unloading valve, which requires an external signal to be activated, typically from a control pressure regulator. The flow must always be constant in some applications, such as ventilators and anaesthetic equipment.