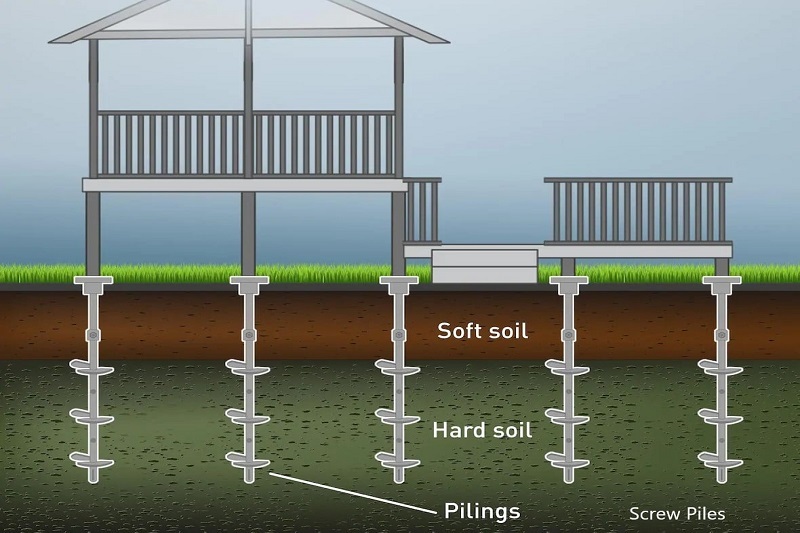

Screw piers are steel screw-in piling and ground anchoring technology use for constructing deep foundations. They are also known as screw piers, screw piers, screw anchors, screw foundations, ground screws, helical piers, helical s, or helical anchors. High-strength steel is commonly use to create screw piers, and various-size tubular hollow pieces are use to create the pile or anchor shaft.

What is a screw pier?

Screw piers are known by names such as screw plier and screw foundations. These are available in different types as well. They are cut into the soil with the help of tools. The helical flights, as well as the shafts, are made in a way to bear the ground conditions. The right screw pier helps in the overall construction of any project, and there are specialize sets of machinery that are use to install high quality piers that are calibrate as per the requirement for very tight tolerance.

How to install it?

Like a screw into wood, screw piers are twist into the earth while installing. There are various provisions and type of variations that are essential for drilling into the ground, and only a train engineer can do that.

Skid-steer loaders and 5-tonne to 80-tonne excavators are just a few examples of the equipment. Custom boom configurations equip rotary hydraulic powerheads with torque ratings ranging from 5,000 Nm to 500,000 Nm. The screw pier are connect to the machine via unique driving attachments.

Are screw piers use to build houses?

Screw piers can be use to build houses even. Helical screw pier are ubiquitous and often use to build houses. Basically, it helps in building the base of the house. It involves excavating holes, putting the screws, and then filling it up with concrete. It is comparatively a much easier way of constructing houses in areas where the ground might not be suitable for heavy construction.

Screw piers are suitable for long time usage.

The screw pier can be use for long-term usage. These piers need to be of excellent quality. Base on the quality of the piers, these can last for 75 years. It also depends on the soil conditions as well. There are even products available that are certify and corrosion resistant. Having the best screw piers can make them last for so many decades.

Usage and benefits:

The use of screw piers is widespread and has spread from lighthouses to the rail, telecommunications, and road sectors, among many others, when quick installation is necessary or where building work must be done near pre-existing buildings.

There are lots of residential applications that are relate to the working of screw piers:

Residential applications for screw pier are already being install, and many homeowners prefer them over other solutions. Helical pile foundations are frequently use for residential decks, sheds, cement pads, prefabricate staircases, and grade beams.

The design of contemporary screw piers is base on accepte geotechnical and structural concepts. Typically, screw pile designers employ proprietary design software they have create after field testing various compression pile and tension anchor configurations in various soil profiles. Corrosion is address in long-term field tests and global databases on steel in-ground corrosion.

Piers and how they connect to concrete during any construction process:

- For connecting to different concrete or steel structures, large load capacity screw pier may feature a variety of components, including flat half helices, Bisalloy cutting tips, helices, cap plates, or re-bar interfaces.

- Due to cost savings and – increasingly – less environmental effect, most companies employ screw piling specialists.

- By screwing’ the foundations into the ground, less earth is move, and hence less soil needs to be remove, saving on transportation expenses, and lowering the project’s carbon imprint.

Conclusion

Shorter project durations, ease of access, reduce carbon footprint, simplicity of removal when foundations are no longer need, the decrease risk to labor, and lower costs are some of the critical advantages of screw pier.

They are also utilize for masts, signage, and retaining structures since they can withstand both tensile and compression stresses. If there is no proper plier, then the drilling process cannot be perform. The land is select first, then soil is check again, measure and then the piers are install. After all the piers get pour, then the leftover soil gets remove.