Key Takeaways

- Understanding the basic functionality of decanter centrifuges.

- Insights into how decanter centrifuges improve wastewater treatment efficiency.

- Real-world applications and benefits of these systems.

Introduction to Decanter Centrifuges

Decanter centrifuges, also known as solid bowl centrifuges, play a pivotal role in effectively treating wastewater. The Importance of Decanter Centrifuges in wastewater treatment cannot be overstated, given today’s environmental sustainability imperatives. With their ability to efficiently separate solids from liquids, these machines are indispensable in various industries like food processing, municipal waste management, and even the textile sector, where they aid in environmental conservation by recycling dyes and chemicals.

Over the past few decades, technological advancements have made decanter centrifuges more effective and reliable. These advancements include enhanced materials with excellent durability and automation features that simplify operations. This article aims to shed light on how these systems work and their broad applications, providing valuable insights into their advantages and future trends.

How Decanter Centrifuges Work

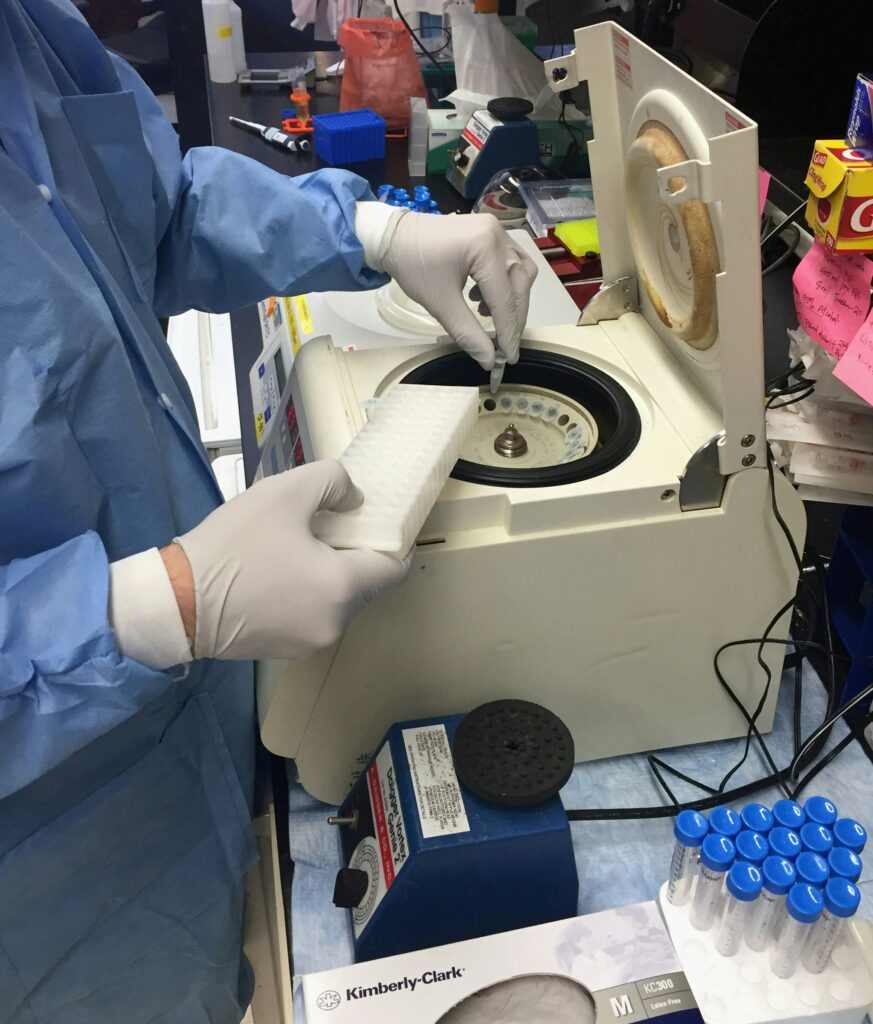

At their core, decanter centrifuges operate on the principle of centrifugal force. When wastewater is fed into the centrifuge, high-speed rotation causes the denser solid particles to move outward to the bowl’s perimeter. In contrast, the less dense liquid remains in the center. Thus, the separation process depends heavily on the differential densities of the treated components. The centrifugal force generated through the high-speed spinning accelerates the sedimentation process, allowing quicker and more efficient separation than traditional methods.

A scroll mechanism moves the separated solids out of the system, effectively scraping the sides of the bowl where they accumulate. Meanwhile, the clarified liquid exits through a different port. This automated and continuous process reduces the need for manual intervention and enhances the overall treatment speed, making decanter centrifuges indispensable in modern wastewater treatment facilities.

Benefits of Using Decanter Centrifuges in Wastewater Treatment

- Efficiency: Decanter centrifuges enhance the overall efficiency of wastewater treatment processes by significantly reducing the time required for solid-liquid separation. The ability to handle a continuous feed of wastewater ensures quicker turnaround times, enabling facilities to manage larger volumes without compromising treated water quality.

- Cost-Effectiveness: These systems lower operational costs by minimizing the need for manual labor and reducing maintenance expenses. The longevity and reliability of decanter centrifuges also lead to long-term savings. Automation in advanced models further lowers costs by eliminating the need for ongoing monitoring and manual changes.

- Environmental Impact: Decanter centrifuges support sustainable practices by optimizing sludge management and reducing energy consumption. Efficient separation of solids results in less sludge volume requiring disposal, reducing transportation and landfill costs. These machines contribute to a smaller carbon footprint and compliance with increasingly stringent environmental regulations.

Key Considerations for Implementation

Careful planning and consideration are necessary to integrate decanter centrifuges into wastewater treatment systems. Factors like wastewater type, volume, treatment goals, and budget should be considered. A thorough assessment helps select the appropriate model. Partnering with experienced suppliers and service providers ensures a smooth implementation process. They can provide insights into equipment selection and staff training. Regular training sessions optimize centrifuge performance and longevity. Scheduled maintenance checks identify potential issues early, preventing breakdowns. These practices enhance system efficiency, provide consistent wastewater treatment, and ensure compliance with environmental regulations and operational goals.